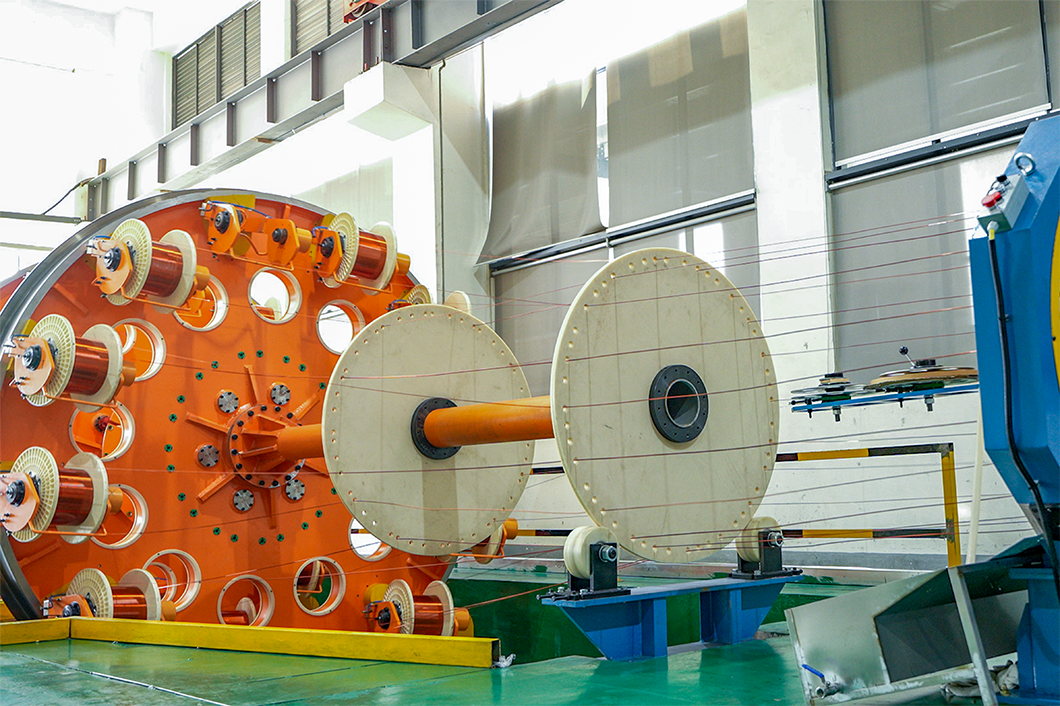

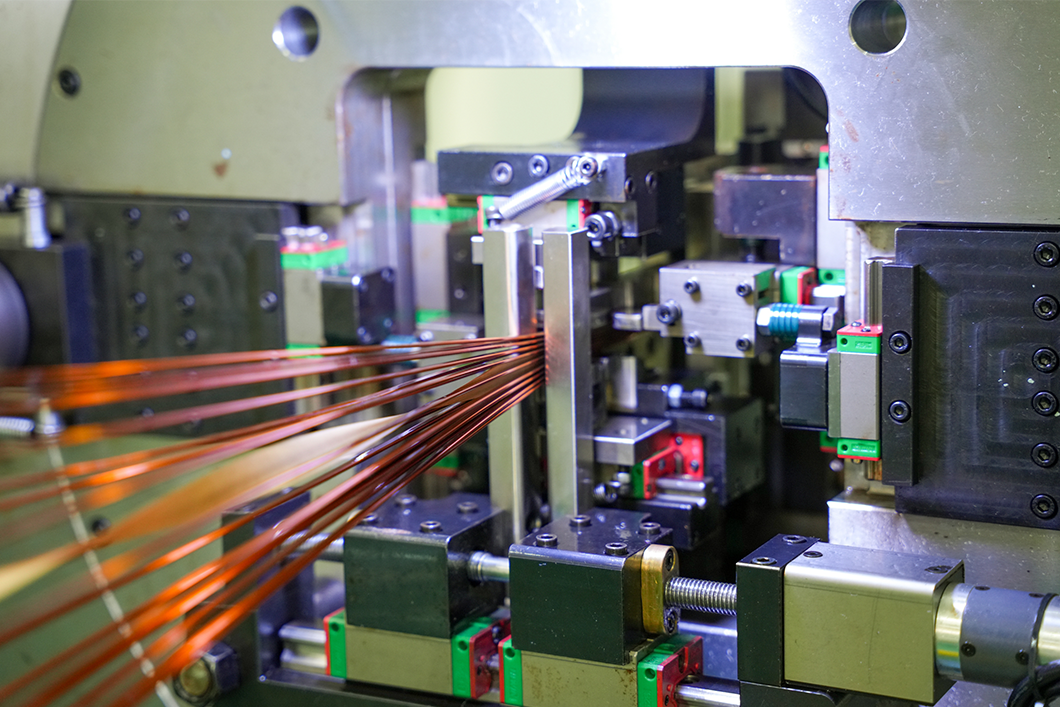

Neustále propletený vodič je důležitým materiálem pro výrobu transformátoru. CTC má Výhody vysokého využití prostoru, nízkých ztrát proudových kroužků, vysoké mechanické pevnosti a méně času na navinutí. Používá se především při výrobě navinutí pro elektrické transformátory, reaktory a trakční transformátory.

Počet propletených vodičů:

5 -- 8 0

Rozměry jednotlivých vodičů:

tloušťka a: 0,90-3,15mm, tolerance ±0,01mm

šířka b: 2,50-13,00mm, tolerance ±0,02mm

Doporučené poměry šířky ke tloušťce pro jednotlivé vodiče jsou 2.0<b/a<9,0

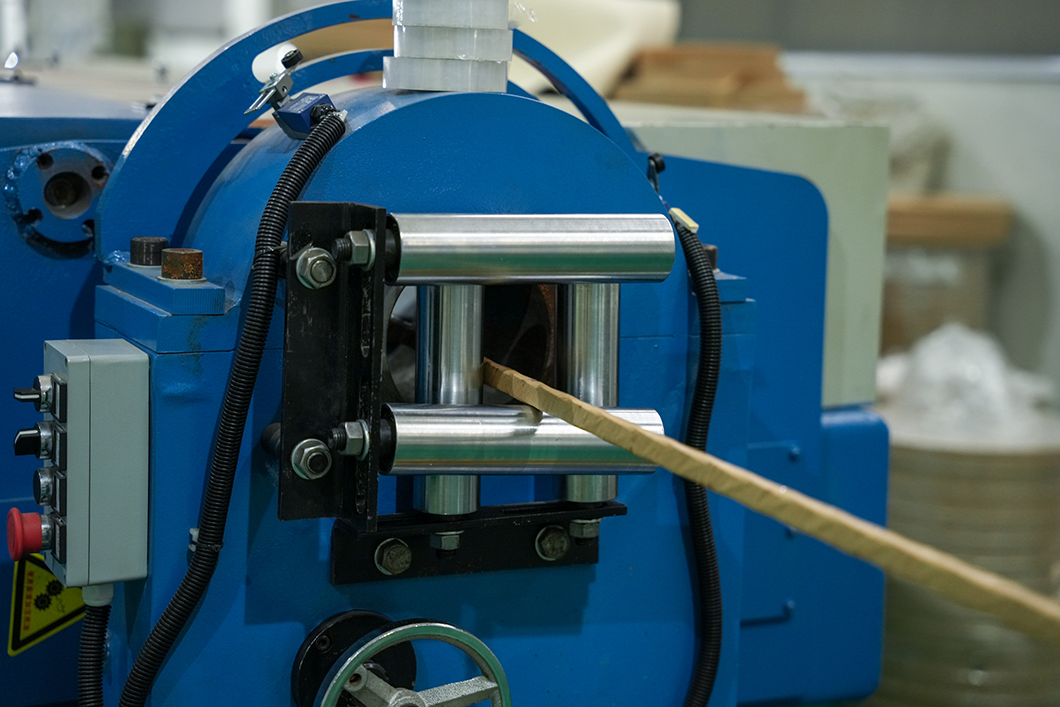

Doporučená tloušťka potahovacího emailu:

0,08-0,12mm

Tloušťka samolepčivého potahu:

0,03-0,05mm

Druhy produktů:

• Papírově izolovaný pvf CTC

• Papírově izolovaný samolepčí pvf CTC

• Papírově izolovaný samolepčí polotvrdý pvf emailovaný CTC

• Bezpapírové spojování pvf CTC

• Polyester-imidový email L ed CTC

• PET foliově izolovaný pvf email L ed CTC

Výše uvedené produkty lze vyrobit podle standardu poskytnutého uživatelem.

Obalové izolační materiály:

•Papír pro vedení kabelů

•Vysokopružný vlákenný papír r vláknový papír

•Papír z vysokohustotního izolačního materiálu

•Aromatický polyamidový papír (Nomex)

•Teplotně odolný izolační papír

•PET film

Uživatelé mohou určit značku, model a specifikace izolačních materiálů.