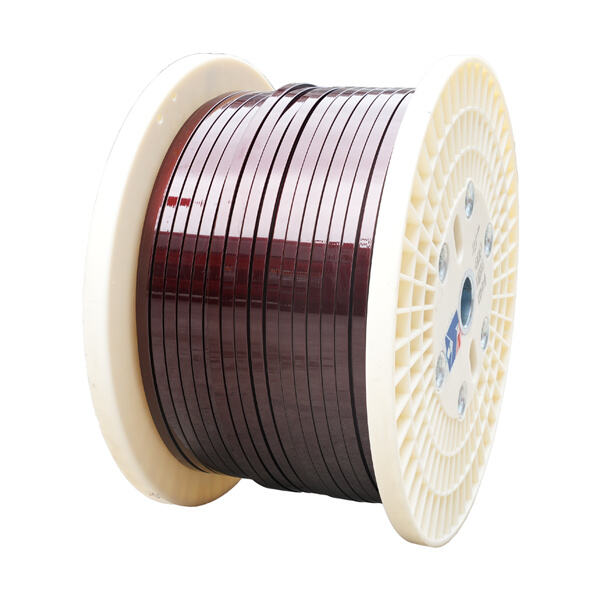

Copper is a metal that plays an important role in many electronic instruments we use daily. This is called enameled copper wire and it is a choice of many people. It is a small wire that has been specially coated to work effectively in electronics, which makes it perfect for many different projects.

The 1 mm enameled copper wire is a specially manufactured type of an enameled kind of the copper tinned cable and its thickness must be scaled in one millimeter. This size is excellent for a wide variety of electronic devices like tiny motors, sensors and other useful tools. It is also a good option for those who tinker with DIY electronics. This wire is loved by a huge number of hobbyists because they're able to use it for all sorts of fun and interesting electronic projects at home.

There are many reasons why 1 mm enameled copper wire is used in electronics. For one reason in particular, electricity can flow through it very well. This is important if we need perfect working small motors and devices that work very well in operation as they must run smoothly as efficiently. This wire also has good conductivity, strength and can tolerate high temperatures. So, it is ideal for the devices that produce a ton of heat because they can work without getting destroyed.

Wire is also very easy to work with so that another great you can use this wire. Small form factor and flexibility is good for projects where you need to fit in tighter spaces or do those detailed projects that require precision work. Its ease in interfacing with other parts and components of their projects makes this an enjoyable language to use for many hobbyists. For that is one reason it finds favor with electronic hackers and DIY designers.

In general, the 1 mm enameled copper wire is a really good solution for those who wish to build accurate and sturdy electronic equipment. With its tiny size being able to excel as a conductor of electricity, it becomes the perfect material for small motors, some sensors and other parts in electronics. It is also easy to use, so it makes a great soldering iron for beginners or professionals with experience in electronics alike.

Our commitment to customer satisfaction extends well beyond the sale of our products We offer comprehensive after-sales services including technical support as well as product education and a responsive team of customer service representatives Our global logistics network ensures prompt delivery and minimal downtime Our team of experts are always available to assist with installation troubleshooting and repair Our winding wires offer you not only high-quality materials but also a partner who is there to 1 mm enamelled copper wire your business at every step

Quality is at the center of all we do We manufacture our winding wires using strict quality control methods and have been certified according to 1 mm enamelled copper wire RoHS and other international standards These certifications confirm that our products are of the best quality and can be used even in the most demanding conditions Additionally we put our money into continuous improvement and innovation regularly making improvements to our production processes in order to maintain our position at the top of the business

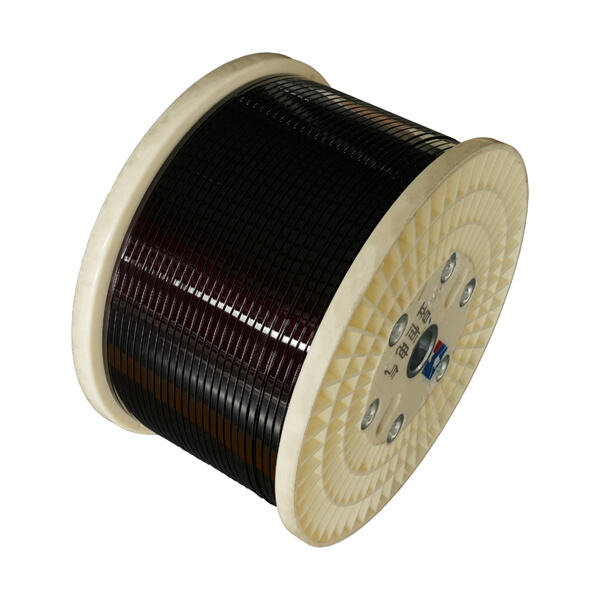

Our company has decades of experience as a top manufacturer within the field We manufacture high-end enameled wires paper-covered wires and wires wrapped in film With manufacturing facilities that adhere to the most stringent industry standards and we serve an international market providing to key industries across more than 50 countries We are a leader in the electrical industry with a wide range of products that meet needs 1 mm enamelled copper wire motors transformers and other electrical equipment

Our products for winding are flexible and offer customized solutions that fulfill the needs of customers Whether you require high-temperature resistance in 1 mm enamelled copper wire to superior insulation or specialized wire sizes or shapes our range of products includes diverse products like aluminum copper and hybrid conductors Our customers work together to design custom winding wires that are designed for the specific applications they are intended to serve The range of applications can vary from small electronic devices to large industrial transformers