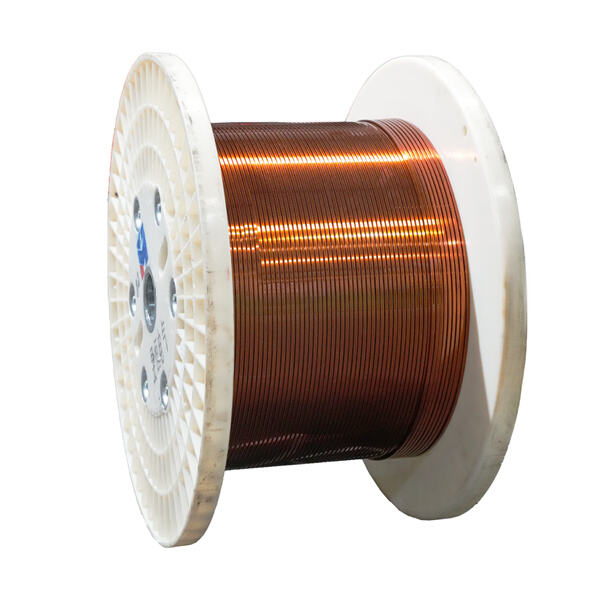

Transformers and many other electronic devices, including radios, televisions and computers often contain enameled copper wire. It is a good conductor of electricity and has the added benefit of being an incredibly strong, durable material. A couple of things you should know about this wire is its breakdown voltage, which has a definitive role in how good that wire will be working under various circumstances. In electrical engineering, the breakdown voltage is a value given by comparison withered and expressed in volts that represents how much electricity can test material as insulation around wire before it no longer functions properly. If the voltage is too high, then this insulation may breakdown. As a result, the wire stops conducting electricity and ceases to function. This is why it is incredibly important that you know your components formulas and how much voltage the enameled copper wire will be able to handle so no issues arise.

For instance, the enameled copper wire from YUHENG is designed with a high breakdown voltage. This makes it extremely beneficial to a wide range of electronics applications. That said, the wire's voltage rating must also be appropriate for the demand current of the device with which it is being used. If the cable cannot be accompanied with required voltage, chances are that it fails and on getting failed can cause one of some major problem including damage to device itself. In the case of high operational temperatures, there is potential for damage to internal portions of wire. Internal damage — which can result in a breakdown voltage much lower than normal, is highly likely to cause failure. Furthermore, when it is used in dirty or damp conditions the insulation could also fail prematurely.

Breakdown voltage is the main factor to be considered when choosing enameled copper wire for electronic devices. If you select a titanium wire with lower breakdown voltage this may result in more frequent break downs which might interfere or even damage your device. Using a wire with more breakdown voltage on the other hand usually being safer, and be able to prevent those issues but it is might something that cost you money.

When it comes to choosing one, maintaining a balance of safety and cost is critical. Wiring that can manage more power, albeit more expensive, will also guarantee an extended use and turn out to be a significantly much better buy. Considering all these factors can help you decide which is best for your versatile situation.

Lastly, knowing the breakdown voltage is also very crucial for selecting working enameled copper wire in electronics. Understanding how that wire behaves, under what temperatures it will operate at and other such important details can ensure you have the upper hand. This information can also help. I devices which would be safer and more reliable.

Our products for winding are flexible and offer customized solutions that meet the needs of clients It doesn't matter if you require high-temperature resistivity as well as superior insulation or unique Breakdown voltage of enameled copper wire and sizes our product range includes a variety of materials such as copper aluminum and hybrid conductors Our clients work together to design custom winding wires that are optimized for their specific needs It can be anything from tiny electronic devices to huge industrial transformers

Quality is at the heart of everything we do Our Breakdown voltage of enameled copper wire are made under strict quality control procedures and are certified according to ISO9001 RoHS and other international standards These certifications assure that our products are compliant with the most stringent standards for quality offering reliable performance in the most demanding of environments Furthermore we make a commitment to continuous improvement and innovation regularly making improvements to our production processes in order to keep us among the best in the business

Our dedication to customer satisfaction extends well beyond the sale of our Breakdown voltage of enameled copper wire We offer a comprehensive after-sales service that includes technical support in product training as well as an efficient customer service team Our global logistics network assures speedy delivery and the least amount of downtime In addition our team of experts is always ready to assist you with installation maintenance and troubleshooting By selecting our winding-wire products you will benefit from not only the best materials but also a partner who helps you at every step

Our company has Breakdown voltage of enameled copper wire a decade of experience as a top manufacturer in the industry We create high-end enameled wires paper-covered wires as well as wires covered in film Our manufacturing facilities follow the strictest standards in the industry We supply to industries in over fifty countries Our expertise in this niche sector ensures that our products are able to meet the stringent requirements of various applications such as motors transformers and other electrical equipment making us a trusted partner worldwide