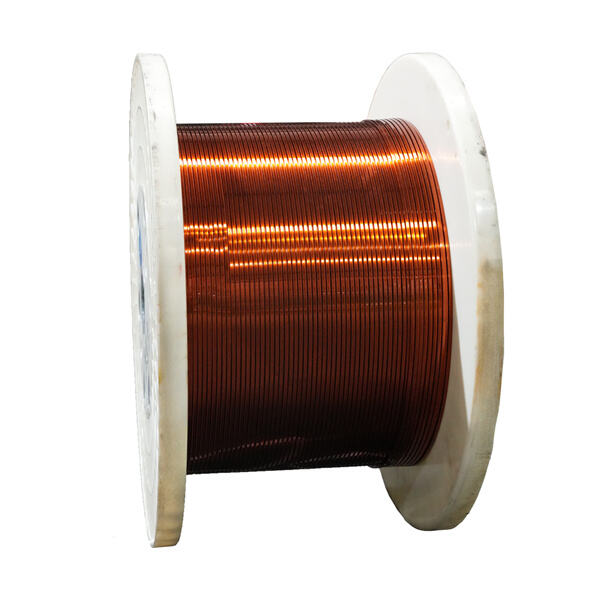

Copper wire enamel coating

Electricity is most often transported via copper wires, which are key components of many machines and electronic devices we use in our daily lives. They are what carry, the electrical current that run all of our modern conveniences such as lights, computers and household appliances. One such company which produces special enamel coated wire to safeguard these copper rubbing cords from damages and disfiguration over time is YUHENG.