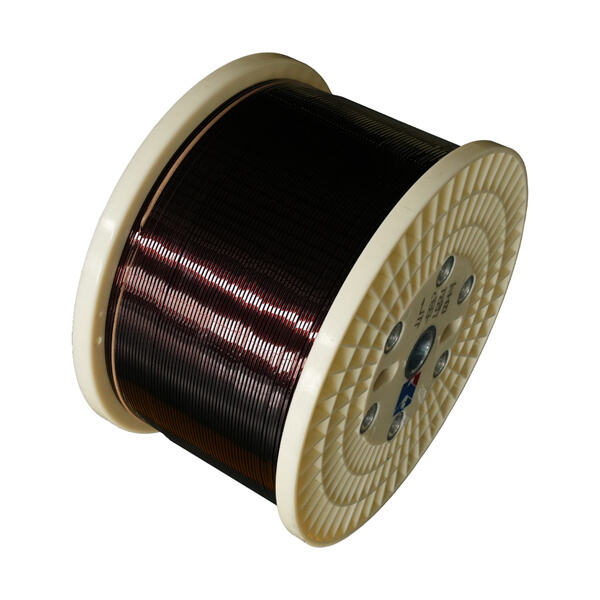

The enamel winding wire is a kind of special wire which can produce numerous kinds of electronic products. You may have noticed this in ordinary articles such as television sets, radio and yesterday’s additional systematic invention–the Mobile Phone! It is enamel wire in imitation of the special native surrounding that enameled urged. For that to be so, they must have had a special covering around it to protect it from being destroyed and to ensure that it smoothly runs for hours. This article will provide you with some brief introduction of YUHENG enamelled wire, whether where it can be used in general and what application.

Enamel conductors are normally made of thin and ductile metal such as copper or aluminum. The above layer is enamel while the one below it is paint for heat/friction. It is for the enamel to shield the wire so as not to easily brake or wear out rapidly. Besides, this coating also facilitates the wire in conducting the electricity voltage and that is useful in electronics products of all kind.

This is one of the main reasons that it has been incredibly favored over the years because of the added benefits that include higher strength and sturdiness. This enamel coating means that the wire will not wear out since anything that might damage it is prevented to make the wire last longer while requiring minimum maintenance. And this is something most relevant in that unique but very common area of use of electronic gadgets which we are constantly in contact with. Enamel wire is far more efficient an electric conductor than most wires that are commonly used. That means it is very conductive of electricity so it can pick up energy from a battery and do not waste much of it as it is utilized in a myriad of devices

First of all, you have to take into consideration such factors when choosing the enamel wire of your project. The first step is to determine what kind of wire you will be going to need. YUHENG enamel wire is generally divided into two type: copper and aluminum. A thicker copper wire which costs a little more, stronger and better conductor of electricity than the common black copper wire. While on the hand, aluminum wire is cheaper than copper but still not strong or efficient to be used on transmission of electricity.

In the end we come back to a hard layer, the enamel covering on the cable. This is perhaps one of the greatest strengths in regards to different types of enamel coatings: each of them has its own capability. A heat, high-heat glass coating will prove more effective in high temperatures than one which is rubbed on or scratched off because of heat. Choosing the right coating is very important considering the whole outcome of the project.

The adhesion of enamel to the wire is an important characteristic which is considered in some wire TSTs. In the event the coating starts to flake or to peel off, it will be clear that the job was done improper and the surface not well coated. It will be challenging for the wire and may well work defectively. To Avoid This Problem, Also, Choose High Quality Enamel With Adhesion Characteristics Are Also To Be Preferred.

When you select and use the magnificent enameled winding cord problems arise in hrs. For example, wire breakage is one of essential issues in the consumption of this product. This shrinks the wiring and if bent often, or exposed to high heat, then the wiring can easily be damaged. YUHENG enameling wire has to be handled gently to prevent breaking, bending the wire which may lead to ear fatigue and cracked insulation as influenced by high temperatures during soldering.

Our commitment to customer satisfaction extends well beyond the sale of our products We offer comprehensive after-sales services including technical support as well as product education and a responsive team of customer service representatives Our global logistics network ensures prompt delivery and minimal downtime Our team of experts are always available to assist with installation troubleshooting and repair Our winding wires offer you not only high-quality materials but also a partner who is there to Enamel winding wire your business at every step

Our company has decades of experience as a renowned manufacturer within the industry We make high-quality enameled wires and Enamel winding wire wires and wires that are wrapped in film Our manufacturing facilities adhere to the strictest industry standards We supply industries in over fifty countries We are an industry leader in the field of electrical technology with a wide range of products that meet requirements of motors transformers as well as other electrical devices

Quality is at the heart of everything we do Our winding wires are produced in strict quality control processes and are backed by ISO9001 RoHS and other international standards These certifications ensure that our products are of highest quality and perform Enamel winding wire in the most challenging environments We also focus on innovation and continuous improvement updating our production technology regularly to ensure we stay at the top of our game

Our products for winding wire are designed with a wide range of options in mind and offer customized solutions that are Enamel winding wire to the specific requirements of our customers Our range of products are available in a broad range of materials that include aluminum copper and hybrid conductors We collaborate closely with our clients to develop specific winding wire solutions to provide the highest performance in their specific applications from small-scale electronic devices to industrial transformers