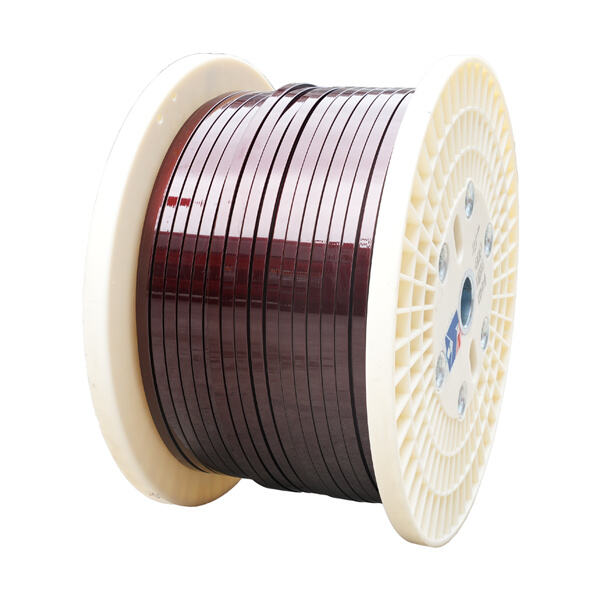

Electrical appliances require a preventive enamel wire coating. It ensure the safety of wires inside them. Uncovered wires are easy to break Such damage can stop the working of appliances completely. Wires are fortified and more durable by layering them with enamel. If we introduce the company YUHENG, this YUHENG enameled copper wire can help you meet with your expectation on enameled wire coating paint and contribute to lengthen life-span or quality of electrical appliances.

There are a lot of reasons that you might want to use enamel-coated wire in your circuits. One of the biggest benefits is over-enamel insulation helps to prevent electrical discharge from leeks. This quality is necessary so that electricity does not escape and consequently causes problems like short circuits, or even more serious risks such as electrical shocks. In addition, enamel-coated wire is more waterproof and rust-proof. That is why electrical home appliances can live so much longer when created with this extraordinary copper cord. Using YUHENG copper wire with enamel results in more reliable, repair-resistant products built by designers and developers alike.

When working with electronic appliances or designing circuits, it is crucial to understand how enamel wire coating works. Enamel is a form of polymer-resin blend material. When wire is coated with enamel, a thin shield that prevents electricity from escaping. The YUHENG copper enameled wire coating also provided the wire same from water, moisture and scratch damage. Understanding how the process work can help you make better choices on your devices electrical systems.

Tips for choosing the right enamel wire coating manufacturer for your project The first thing you should consider before doing this calculation is how much voltage and current your circuit needs. There are an enamel coating with the intended voltage and current levels in mind, so is really necessary to choose rightly your targeted one. Also take into account the wires you are using. The enamel coating may or not be compatible with different types of wire. Spending some time figuring out the right coating can make a huge difference in how long your work lasts.

For those looking for the most durable, high-quality well made electronics will need that extra assurance of enamel wire coating to make their product last as long possible. They can withstand being banged up, and last longer with use than products that are made using metal wires. The enamel coat is also capable of protecting wires from water and rust, which are both elements that can seriously harm the system in time. This makes perfect coating of wires crucial for avoiding issues that may otherwise require extensive repairs or total replacements down the line.

Our winding wire products are designed with Enamel wire coating in mind offering customized solutions that are tailored to the specific needs of our clients Our product line is available in a range of materials that include aluminum copper and hybrid conductors Our clients collaborate together with us to design winding wires that are optimized for their needs These can range from small-scale electronic devices up to huge industrial transformers

We're Enamel wire coating to provide our customers with a high degree of satisfaction This is not just a purchase We offer a wide range of after-sales service that include technical support along with product education and an efficient team of customers service reps Our global logistics network ensures prompt delivery and low downtime Our expert team is at hand to assist with installation maintenance and troubleshooting Our winding wire products provide the highest quality materials but also a partner that will assist you at every step

Our company has Enamel wire coating a decade of experience as a top manufacturer in the industry We create high-end enameled wires paper-covered wires as well as wires covered in film Our manufacturing facilities follow the strictest standards in the industry We supply to industries in over fifty countries Our expertise in this niche sector ensures that our products are able to meet the stringent requirements of various applications such as motors transformers and other electrical equipment making us a trusted partner worldwide

We're committed to quality in everything we do Our winding wires are produced using Enamel wire coating methods and are backed by ISO9001 RoHS and other international standards These certifications guarantee that our products are of top quality and are reliable in even the most demanding environments In addition we put our money into continuous enhancement and development frequently changing our production techniques to maintain our position at the top of the sector