Electrical transformer very critical part of electrical system I hope you will know, just like the YUHENG's product called magnet wire. They no longer need magnets to shift the energy around. Transformers are everywhere in our everyday lives, from radios and cell phones to power lines that reach into our homes and schools. How transformers works: Now you will Understood Easily the technology Behind us.

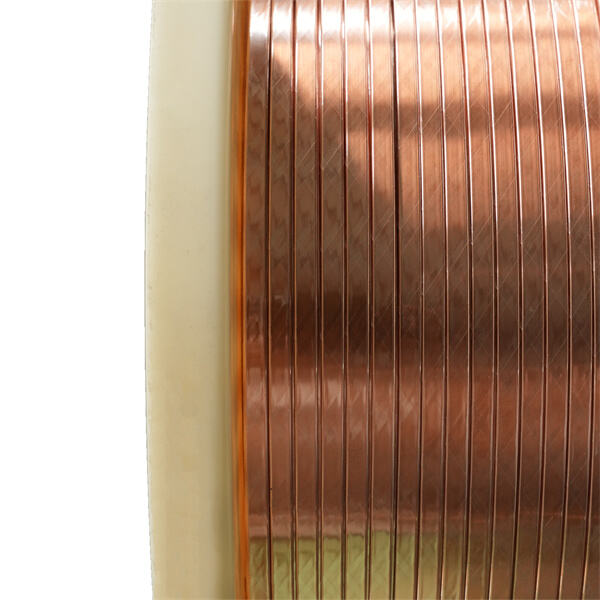

Transformer Winding is mainly used for enhancing the competence and effectiveness of a stated or definite employed machine function, similar to the enamel coated magnet wire made by YUHENG. Winding: It is copper wire wound around a core component. The magnetic field created by this wrap is what allows the transformer to operate. Copper wire is used for this as it has some excellent qualities — conducting electricity very efficiently, with low resistance (which basically means a current flows through easily).

The key reason is said to be the copperwire for transformer compared with Aluminum wire, that consumers view it can carrying rebatement of electricity damage, identical to YUHENG's product 14 gauge magnet wire. This is particularly important in the case of larger transformers for which a tiny bit of energy loss can have considerable consequences. Furthermore, the fact that a lot of electricity can go through copper without short-circuiting and as a consequence high temperatures not being transfered to the transformer. That can definitely present a overheating issue, and we never input that. Copper is also very long-lasting; it can withstand any kind of temperature and weather condition which makes it choice material for several purposes.

Copper Wires Transformers are mainly used to send power easily from one place to another, the same as copper winding wire made by YUHENG. The other half of it is active ingredient is copper, and without this form available in the soil, it can no longer function. The resistance of copper makes the wire get too hot and gives energy off what is intolerable. However, copper has lower resistance than other substances are capable of handling a greater power while remaining cooler. This also helps the wire to transfer more energy to the transformer and so, it makes whole system work better.

Generically transformers are understood as copper wire, which is an application of both the general theory of electricity and magnets, similar to the YUHENG's product like ecca wire. The copper wire is then wrapped around an iron core in order to produce an electromagnetic field. This is the origin of how the transformer works. The last part is there for black and white polarity; when attached to the terminals of a electricity supply, it allows current to pass. The magnetic field then runs around the electrical current making a powerful new magnetic field able to transport energy all over many circuits. And you must also wind the wire around that key so many times. One simple answer is that it can neither be tuned too few nor too many times The winding has to be repeated a certain amount of times or you will not generate the required magnetic field.

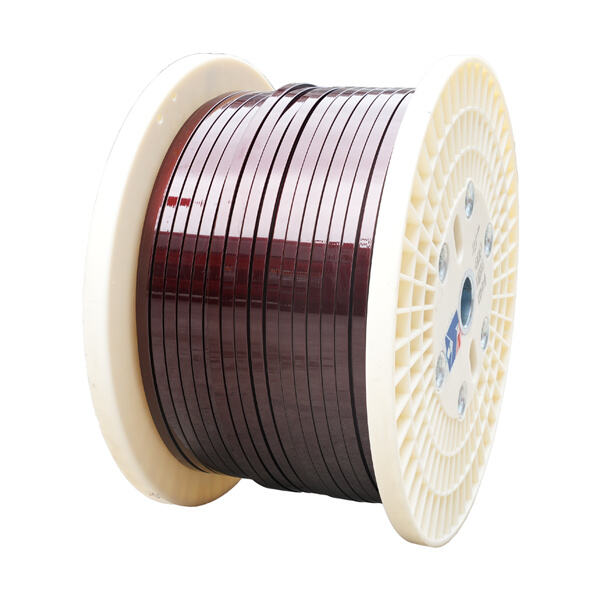

Our products for winding wire are designed with a wide range of options in mind and offer customized solutions that are tailored to the specific needs of our clients Our Transformer winding copper wire of products are available in a range of materials which include aluminum copper and hybrid conductors We work with our customers to create customized winding wire solutions that provide the highest performance in their respective applications including small-scale electronics to industrial transformers

Transformer winding copper wire are committed to excellence in all that we do Our winding wires are made using strict quality control methods and are certified according to ISO9001 RoHS and other international standards These certifications assure that our products are of the top quality and are reliable in the most challenging environments We also focus on innovation and constant improvement enhancing our production technology regularly to ensure we stay at the top of the line in our industry

Our company has decades of experience as a leading manufacturer within the industry We manufacture high-end enameled wires wires covered with paper and wires that are covered in film Manufacturing facilities adhere to the strictest industry standards we cater to the global market and provide essential industries across over 50 nations We are a leader in the field of electrical technology with a vast array of products to meet the needs of motors transformers and other Transformer winding copper wire

Our commitment to customer satisfaction extends well beyond the purchase of our products We offer a wide range of after-sales service such as technical assistance along with product education and our customers service reps Our global logistics network guarantees quick delivery with minimal downtime Our expert team is there to assist with installation troubleshooting and repair Our winding wires offer you not just top-quality products but also a reliable Transformer winding copper wire who supports your operation at every step

YUHENG carefully makes transformer specialty copper wires, just like the electric motor winding wire developed by YUHENG. And the products in our company are made using good quality materials and a great manufacturing process. Our copper wires are very efficient and durable as well. In short, they last a lifetime long-term in the harshest of conditions. This gives our clients the confidence that using our products will allow them to securely and sustainably transmit energy into the future. Therefore, YUHENG copper wire are able to be customized and applied efficiently in every transformer from small electronics up to systems that keep an entire neighborhood running.