Wire enamelling allows you to make drab wires into beautiful, colorful and shiny functional pieces. How do they acquire this special skill is some creative ways that are learned overtime with practice. You also want the right tools to make sure you get started correctly. We are proud to be skilled in wire enamelling at YUHENG As a matter of fact we honestly feel that this wonderful craft can help many people to make beautiful jewelry and what's even better is everybody at any age would love it.

When you start with wire enamelling, there are some essential tools available to assist. Essential tools: pliers, wire cutters and a torch You will use a pair of pliers to hold and form the wire, as well as wire cutters in order to make specific lengths of your coil-on-pipe. To make the enamelled wire, enamel stick molecularly to it was attached, a torch is used. You will also have to buy enamel powder, which is a kind of special colored glass that can survive very high temperatures without bursting. It is essential to clean the wire thoroughly before applying the enamel. Wiping over the wire makes sure that you are removed all dust, dirt or grease. The enamel is bonded to the wire and keeps the individual wires attached so you can use it for making your beautiful designs.

But the real beauty with wire enamelling is in its capability to convert plain wires into even more beautiful and complex designs. It will take practice and the right tools to get good at making beautiful patterns, shapes and colors that sets your jewelry apart from others. You will be able to make all sorts of lovely creations like earrings, necklaces, bracelets and other jewelry accessories. Some of these YUHENG jewellery items can help you give that extra added beauty and elegance to your outfits making you standout in any setting.

One of the most essential things, being in wire enamelling is to come up with designs that enamel wire are beautiful. And not just any colors but combinations of the right ones. A great way to do this is simply put two and three together, by selecting two colours you know look good with each other You can also play with those designs by adding new shapes and patterns that are attractive yet extraordinary. You can also experiment with wires of different textures and thickness to create even more interesting results in your jewelry. Making these necklaces can take many forms, and every one will be unique to your own style preferences.

To achieve maximum quality of design and finish in this enameled wire field, one needs to do is be patient, imaginative at creating designs as well as adaptable for learning new wire enamelling techniques. YUHENG is providing programs classes and workshops for all age of people. In these programs, they are imparted the basic wire enamelling skills and techniques. After getting used to it a bit and with some advice from our talented instructors you'd be able to enhance your own talents which could lead picture perfect jewellery designs that reflect the real YOU!

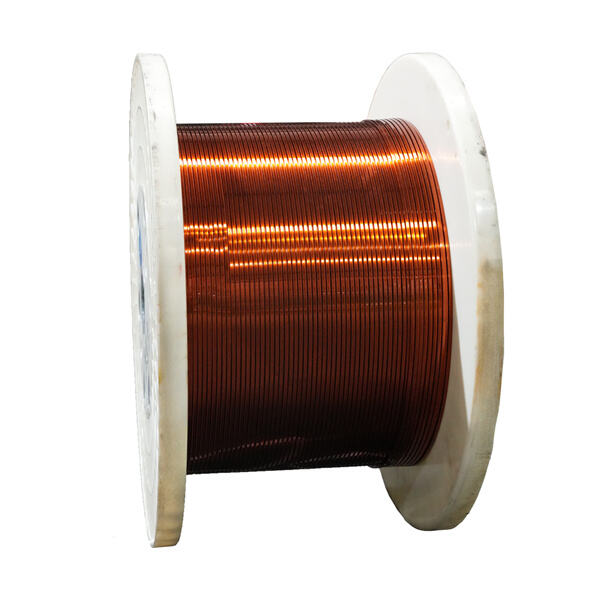

Applying enamel powder to the bare wire that has been heated using a torch. When this enameled copper wire has been achieved, you heat up the wire for a second time so that when molten enamelling glass is applied to the surface of the wire it melts and glazes blocking rust from attacking.

Enamel bonded to metal – This copper wire with enamel method is when there a piece of enamel power on the surface of a hot piece of warm metal. It melts and then bonds into the metal when you heat it again.

Wire enamelling company has over a decade of experience as a leading manufacturer within the field We make high-quality coated wires paper-covered cables and wires that are wrapped in film Our manufacturing facilities comply with the strictest standards in the industry We supply to companies in more than fifty countries Our experience in this industry ensures our products can meet the demanding requirements of a variety of applications such as motors transformers and other electrical equipment which makes us a trusted partner worldwide

Quality is at the heart of everything we do Our Wire enamelling are made under strict quality control procedures and are certified according to ISO9001 RoHS and other international standards These certifications assure that our products are compliant with the most stringent standards for quality offering reliable performance in the most demanding of environments Furthermore we make a commitment to continuous improvement and innovation regularly making improvements to our production processes in order to keep us among the best in the business

Our Wire enamelling are versatile and provide customized solutions to will meet the demands of clients Our range of products are available in a broad range of materials such as aluminum copper and hybrid conductors We collaborate closely with our clients to create specific winding wire solutions to guarantee optimal performance in their specific applications from small-scale electronics to industrial transformers

We are committed to providing our customers with the highest level of satisfaction and this is not just a sale We offer comprehensive after-sales services like technical assistance along with product education and our customer service representatives Our global logistic network ensures rapid delivery and low downtime In addition our expert team is at hand to assist in the installation maintenance and troubleshooting By choosing our winding wire products you will benefit from not just top-quality products but also a Wire enamelling that will support your business at every stage