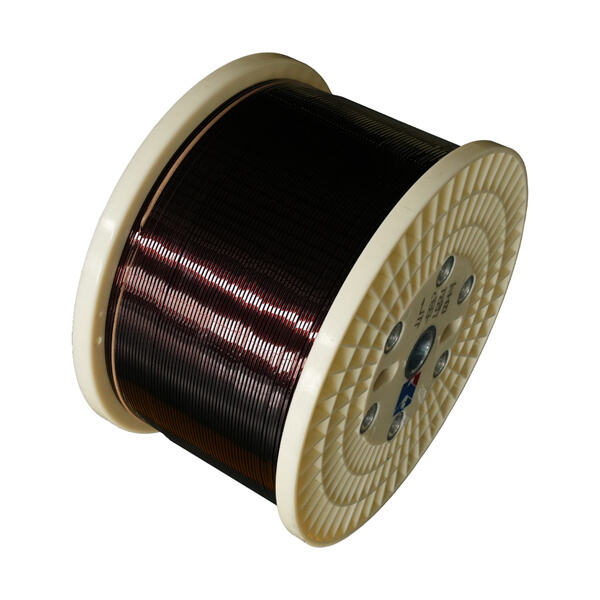

Choosing the right wire when you are doing electrical projects. Choosing the right kind can make a real difference in how well your project operates. 24 AWG magnet wireOne of the more popular types of wires people use. This wire ranks high in strength and dependability, making it a top choice for advanced as well as novice hunters. Today, we will dive into 24 AWG magnet wire and who uses it, different types of the wiring on the market and so much more.

Power Consumption: Also YUHENG magnet with copper wire can easily let the current pass through it so gives power consumption efficiency. It is an important property for the normal function of every electronic. Without a good flow of electricity, devices may stop acting the way they should. Also, this wire does not corrode which enables it to maintain corrosion for a longer time period. Its resistance to high temperatures also makes it perfect for working in the all kinds of tough industrial environments and environments in which things are hotting up.

The insulation is also serves a key role as that is what keeps the wire from getting ruined and also refinements shorting out. A poor connection is equivalent to a short circuit in electrical devices, so insulation is the name of the game when it comes to maintaining smooth operation. Additionally, this insulation makes the wire way more user-friendly while installing giving it a better grip and flexibility. Basic Usage of YUHENG 24 gage wire because All has It's Features mentioned above and it used In Many Electrical Fields Like Inductors, Motors and Transformers etc.

Choosing the perfect magnet wire when using 24 AWG is a decision that requires just as much thought. The first thing you need to understand is which material of insulation that has been used. Insulation materials differ and the choice of one over another may be more suited to your particular needs. For instance, some materials may function well in water, while other work for high temperature place.

The other aspect you have to look into at the same time is every wire will be rated for a maximum of current and also temperature. This rating is an indicator of the highest temperature the wire can tolerate before melting or being damaged. It is important to choose a wire that will not melt through the great heats of your project. The failure of this magnetic wire by YUHENG on your Device or project is in part due to the structure of the wire and that it can handle the temperature in which the device was exposed.

Finally, you need to consider the thickness of the wire, or its gauge. Although magnet wire is usually 24 gauge, there are wider ones like 23 AWG and a little thinner ones like 25 AWG that suitable for particular. Now you know why choosing the correct gauge is critical; increased or reduced thickness of wire has a direct impact on how much current it allows through and performs in your project.

The kit you get from another supplier could offer more features, like color coding that can simplify the process of installation and identification. One idea is to use color coding, which can be very helpful when it comes to sorting wires and making sure you have the finest connection for what you trying to achieve. There are also unique subclasses of copper wire and magnet which made for applications with high frequencies to very high voltage.

Our company has over a decade of experience in being a major producer in the 24 awg magnet wire We create high-end enameled wires and paper-covered wires as well as wires wrapped in film Our manufacturing facilities adhere to the strictest industry standards We supply to industries in over fifty countries Our expertise in this niche industry ensures our products meet the rigorous requirements of a variety of applications which includes motors transformers and other electrical equipment making us a respected partner across the globe

24 awg magnet wire determined to provide our customers with the highest level of satisfaction This commitment goes beyond the purchase We provide comprehensive after-sales support with technical assistance product training and an efficient customer service team Our global logistics network assures rapid delivery and a minimum amount of downtime Our team of experts is there to assist with installation troubleshooting and maintenance By choosing our winding wire products you'll benefit from not only top-quality materials but also a partner who helps you at every stage

Quality is the core of all we do Wires for winding are manufactured in strict quality control processes and we are certified by ISO9001 RoHS and other international standards These certifications 24 awg magnet wire that our products comply with the highest standards of quality offering reliable performance in the most demanding environments Furthermore we put our money into continuous improvement and innovation regularly changing our production techniques to keep our place at the top of the sector

Our 24 awg magnet wire are versatile and provide customized solutions to will meet the demands of clients Our range of products are available in a broad range of materials such as aluminum copper and hybrid conductors We collaborate closely with our clients to create specific winding wire solutions to guarantee optimal performance in their specific applications from small-scale electronics to industrial transformers