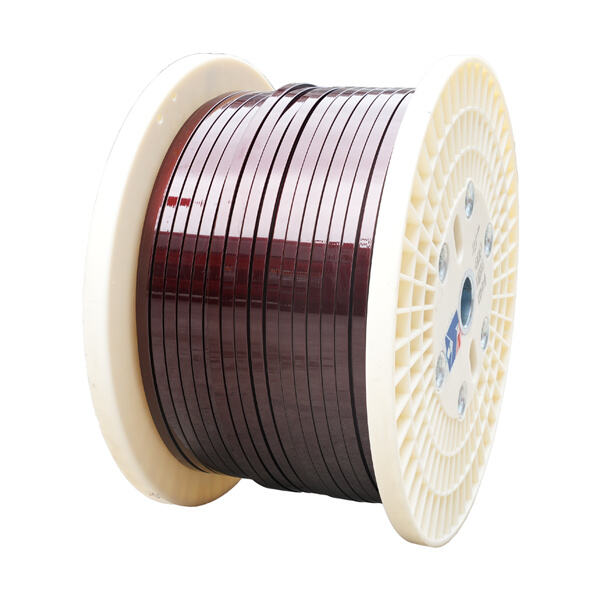

Enamel covered copper wire

Assuming a broad generalization there, copper wire being metal wiring for electricity. It is constructed from copper, a metallic component that carries out power exceptionally well. This YUHENG property is the reason that copper wire has been widely used in making different types of electronics and conducting electricity through wiring. Naturally, there are electrical projects and requirements that plain copper wire alone may not suffice. This enamelled copper wire specifications is why; for many of these requirements enamel covered copper wire shows to be the far better alternative.

The most significant difference between the two is that enamel coated copper wire has a protective cover on it. It is called enamel, which a plastic-like material. This layer of enamel is what protects the metal from rust (which comes from moisture), scratches, and bending; all things that corrode wire's innate strength. This protective coating allows the wire to hold up better over time. It is of the utmost importance to use a specific type of copper wire so that machines and gadgets run flawlessly.