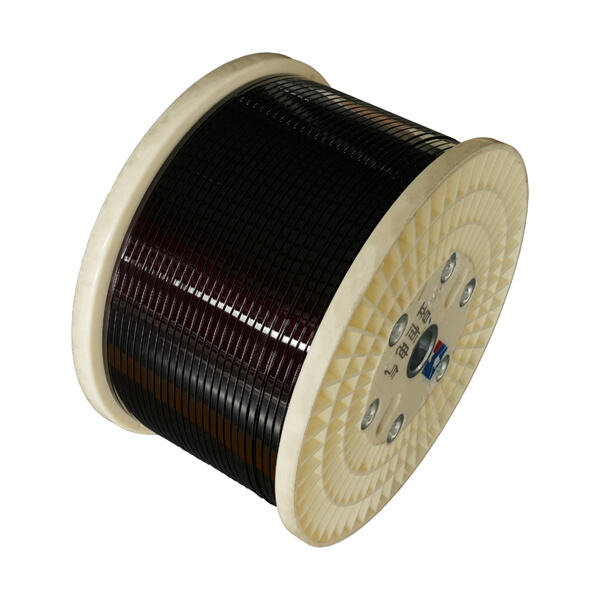

Magnet wire enamel coated

Can you imagine a wire that looks like magnet but has been given a special coating? How enamel wire is unique — Enamel Wire This enamel is crucial as it helps the wire to perform better and have a longer life under many different circumstances. Today, in this particular article we are going to discuss what magnet wire enamel coating is and its advantages from there on how can you decide which one do you choose for your application. Also, we will explain to you why YUHENG magnets wires is the right brand that serves as your answer in scouring for magnet wire enamel-coated.

There are various benefits associated with magnet wire enamel coating and this is why they have become a household name for many. The first is that the coating acts as a shield to protect the wire from damage. What this means is the wire can survive a long time without fraying or breaking out. The enamel also protects it from electrical damages, and other types of damage as well. This is; particularly ideal for use with wires that are commonly exposed to the environment or highly active areas where they may get wet and dirty.